Editors’ Note: This feature appears as it was published in the summer 2019 edition of UT Dallas Magazine. Titles or faculty members listed may have changed since that time.

Lithium-ion batteries have been the hands-down favorite for smartphones, tablets, laptops, cameras and rechargeable power tools for decades. But they also have drawbacks, such as “thermal runaway,” in which a battery fails—or catches fire—due to the buildup of too much heat.

For years, researchers have been looking for the source of the heat problem and how to fix the associated volatility. After three years of material simulation, synthesis, characterization and battery performance tests, UT Dallas researchers have discovered that the problem with lithium-ion batteries isn’t inside the battery materials.

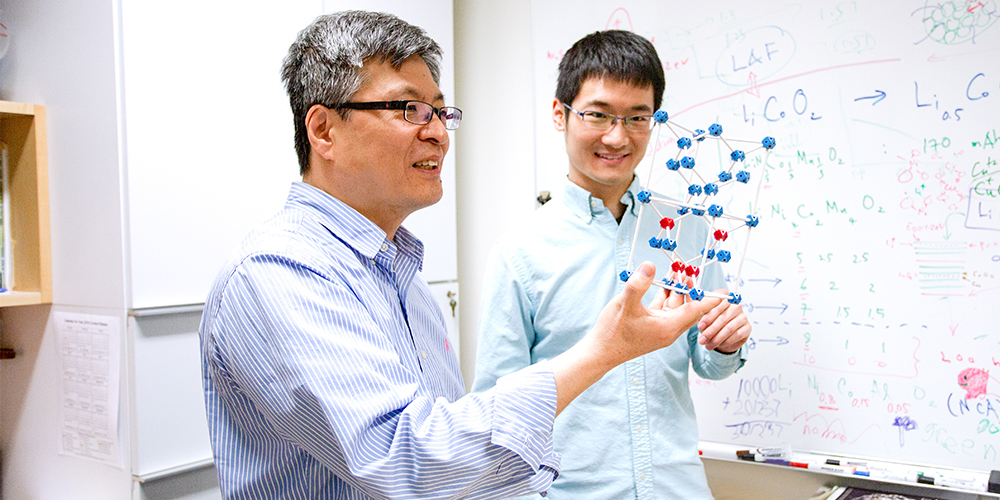

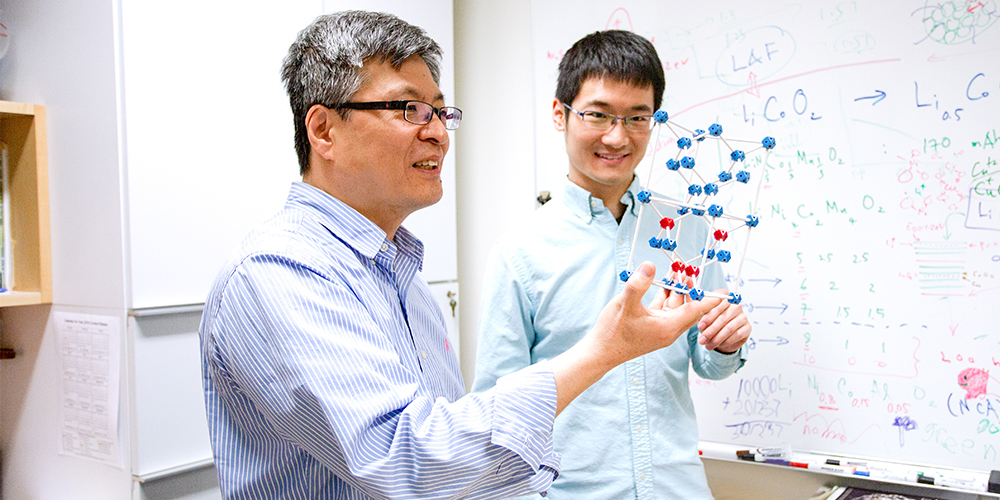

“It turns out only the surface of the battery cathode materials is the problem,” said Dr. Kyeongjae “K.J.” Cho, professor of materials science and engineering. “The inside is OK. This gives us great hope we can figure out how to stabilize the surface and make really high-capacity batteries a reality.”

Cho and his colleagues described their findings in the Jan. 10 print edition of the journal Advanced Energy Materials.

“When a battery is constantly charged and recharged, the material begins to degrade. Released energy causes heating, and the battery catches fire. That’s essentially the safety problem,” he said.

During the constant cycles of charging and recharging, oxygen gases are released from the surface of battery materials. During that process, the pathway for lithium-ion transportation from the interior to the exterior can get blocked by metallic nickel dust, which is generated along with gas releasing, Cho said.

“When there is a blockage, there’s no way to transfer lithium-ions at the surface that want to come in and out. This leads to rapid decrement of battery capacity. As the amount of heat increases, the chances of fire and explosions also increase,” he said.

Cho suggests perhaps a well-designed oxide coating could be added on the battery surface.

“Modifications could lead to maintaining a charge for a longer period of time,” Cho said. “This is the problem industry is trying to solve right now for the next generation of lithium-ion battery. It’s very exciting, and we are working on the next stage.”

Fantai Kong PhD’17, lead author of the study and Cho’s former student, is a senior engineer with Hunt Energy Enterprises in Dallas working on large-scale energy storage and material projects. He said solving the heat problem in batteries could lead to a 20% to 30% higher capacity.

“We are right at the threshold of commercial viability,” Kong said.

The work was supported primarily by the government of South Korea and L&F Co. of Korea.